2D/3D X-ray

2D/3D X-ray- 2D X-ray imaging is useful for quick evaluations and detecting certain surface-level or easily visible defects. In contrast, 3D X-ray imaging offers a more detailed and thorough view, making it especially effective for analyzing complex structures and identifying smaller or hidden flaws. The selection between 2D and 3D imaging depends on factors such as the application, the sample’s size and complexity, and the level of detail required.

3D X-ray imaging is particularly valuable in failure analysis, as it allows engineers to locate internal defects and enhance product reliability. Although some limitations still exist, ongoing improvements in deep learning and related technologies are steadily addressing these challenges, further increasing the power and accuracy of this technique.

How It Works

2D X-rays

- Produce flat images in shades of gray

- Used for routine examinations in dentistry

3D X-rays

- Also known as 3D X-ray computed tomography (CT) or 3D CT

- Provide a comprehensive view for detailed diagnostics and complex treatment planning

- Can be used to analyze complex geometrics

- Can detect defects that might be hidden in a 2D image

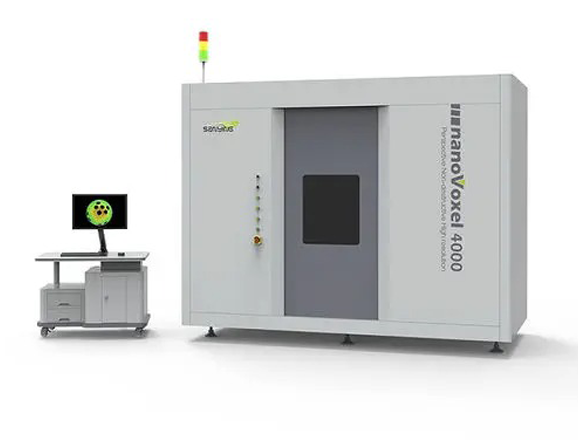

Model name = NanoVoxel-4200 X-ray 3D Microscope

Sample Dimension = (600Lx600H) mm

Max X-ray tube & Power = 20-225kV, 350W

Tube current range = 30-300 micro Amp

Sample weight = 25-30 kg

Distance X-ray tube to detector = 1015 cm